Ok, you've read about how you can 3D print

houses and

airplanes and your very own

fetus, and now you're excited about getting your hands on your own 3D printer so you can start making... you do know what you want to make, right?

We finally got a

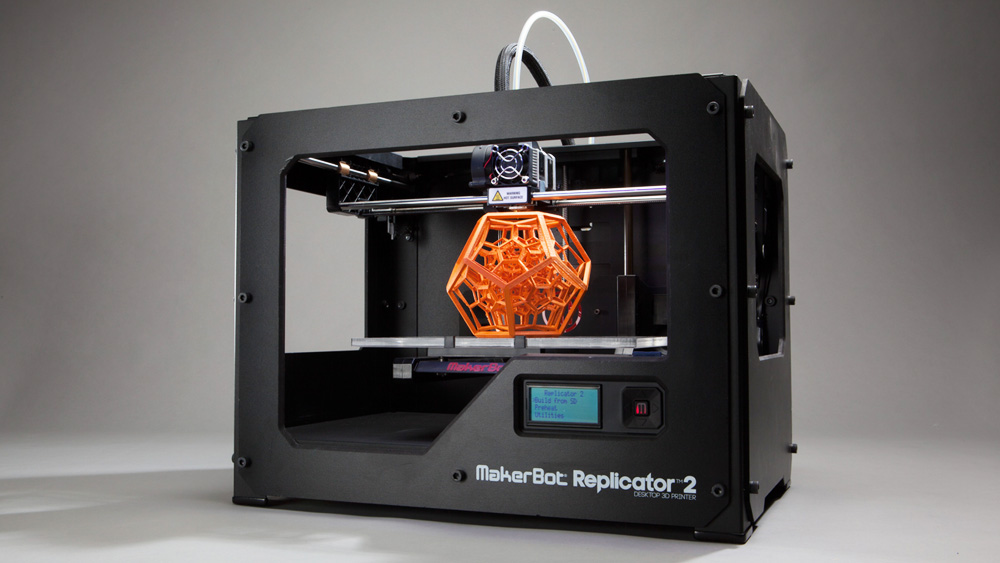

MakerBot Replicator 2 at work. I've been able to use it in a few projects over the last few weeks, and we're actually using it to turn out production parts starting next week. It's been enough time that now I feel comfortable writing up my first impressions, from the point of view of a small engineering design firm.

The Replicator 2 has been an awesome tool for rapid prototyping. A lot of our projects involve designing specialized components for handling in robotic systems. The first day I used the Replicator 2, I was able to design, print, test and redesign three iterations of a small plastic component within a few hours. That's unreal! There really was no learning curve. MakerSoft allows you to import .stl files, position the product, view layer-by-layer print previews and even scale. It really couldn't be easier.

But we all know the benefits of 3D printing for rapid prototyping. What blew me away was how quickly the Replicator 2 turned from a prototype printer to a

production printer. Check out the following example:

- I was exploring producing a small (50g) complex plastic component in the 300-400 quantity range for a project. I used the Replicator 2 to design about 6 iterations and then went about sourcing a manufacturer. After looking at different options, turns out if we print the entire production run ourselves, it will cost 3% of what it would to have it commercially 3D printed. As you might expect, it also comes in much cheaper than building a custom injected plastic mold.

So for a small engineering firm, those numbers are great. In fact, we've actually already paid off our Replicator 2 by printing production parts for a client. Without going into too much detail, they were impressed by the accuracy of 3D printing vs. poured castings for their mold application and approached us about producing their new molds.

There are a few downsides I've noticed working with the Replicator 2:

- It doesn't automatically stop when it runs out of print filament. That really wouldn't have been a hard feature to design in. Running out of filament 90% of the way through a 6 hour print effectively rendered it useless. However, it looks like the 5th generation MakerBot will have that functionality.

- There has to be some sort of automated project output management in the future. Imagine if every time you printed a document in your normal printer, you had to take out the finished sheet before it would start the next one. With the way MakerBots work, every time a job finishes you must manually remove it and separate it from the base.

In conclusion:

For a small engineering business, having a MakerBot on hand can be incredibly useful, even for producing production ready parts. They hit the sweet spot between a small quantity production runs (using expensive commercial 3D printing) and large initial buy in injection molded plastic parts. The only major wish I have is for output automation, so I don't have to respond to MakerBot's "I'm done!" beeps like Pavlov salivating at a bell.